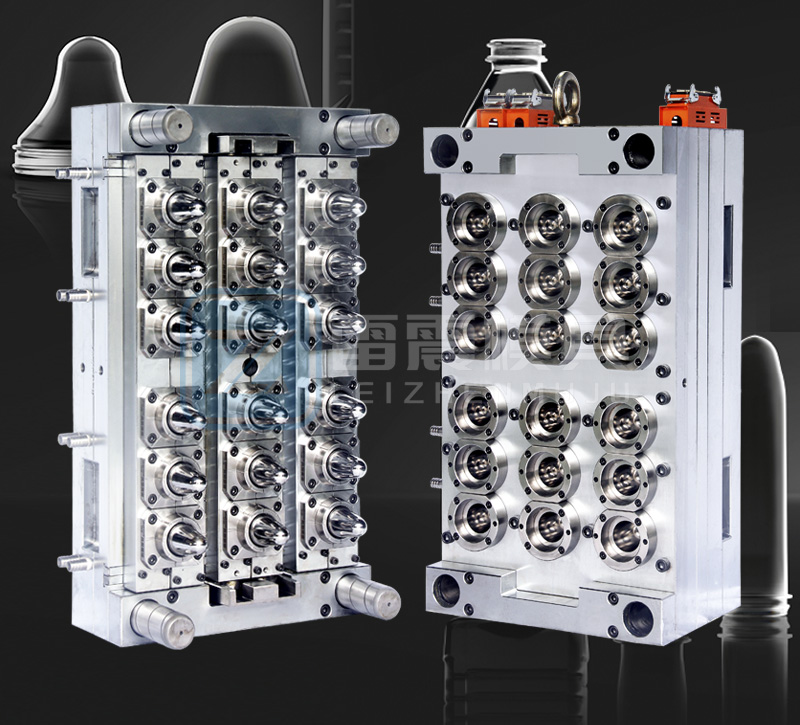

The factory has senior mold engineers with many years of experience, adopts CAD/CAM/CAE computer system, and advanced numerical control processing equipment, and specializes in producing various PET molds (such as: needle valve type, shear-free gate, independent self-locking, Adjustable eccentricity and other new PET molds), high concentricity, ensuring all cavities, interchangeable cores, long life and so on. And the price is reasonable, the delivery is timely, and has been praised and trusted by the majority of customers.

| Technical parameters of PET wide mouth preform mold | |

|---|---|

| Mold name | Thirty-two preform molds with a diameter of 38mm |

| Cavities | 32 cavities |

| Caliber | Caliber 38mm |

| Preform Weight | 55 grams |

| Insert | 2316 stainless steel imported from Germany |

| Template | #50 steel |

| Forming cycle | It takes 45 seconds to produce with a general PET screw injection molding machine |

| Double injection molding system and out-of-mold cooling system (PET Master line) | Injection molding machine with dual injection molding system with 3-station external cooling system takes 24 seconds |

| Hot runner design | Balanced hot runner with needle valve unit |

| Which injection molding machines are suitable | Husky, Netstal PET line, PET Master and other general PET injection molding machines |